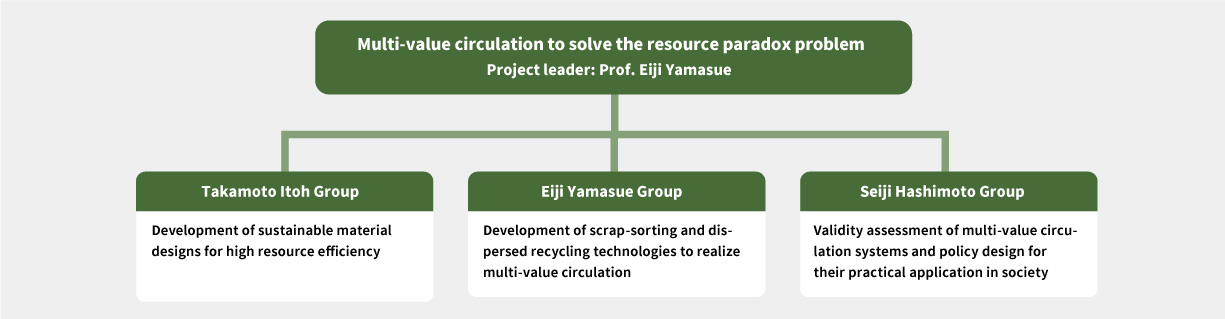

Research AreaⅠ Restoration of the Earth's natural environmentMulti-Value Circulation to Solve the Resource Paradox Problem

Solving the global resource paradox to achieve green innovation in the true sense of the term

Leaders

-

Project leaderEiji YamasueProfessor, Department of Mechanical Engineering, College of Science and EngineeringProfile

-

Group leaderTakamoto ItohProfessor, Department of Mechanical Engineering, College of Science and EngineeringProfile

-

Group leaderSeiji HashimotoProfessor, Department of Civil and Environmental Engineering, College of Science and EngineeringProfile

R-GIRO dedicated researcher

Identifying products causing the resource paradox and proposing solutions through technologies, societal systems, and policy packages

Today, businesses and researchers around the world are working toward green innovation using a wide range of technologies so as to solve the environmental problems confronting humankind. However, some efforts for decarbonization or dematerialization are resulting in opposite effect due to excessive resource use.

Decarbonization and dematerialization cannot be achieved in the true sense of the term unless the problem called the “resource paradox” is solved: Decarbonization and dematerialization, deemed successful when measured in direct weight, often require large quantities of resource-mining activities, that is, resource consumption. This is the case in Japan, according to the project leader, Prof. Yamasue. He has been assessing the resource efficiency of a broad range of products using the indicator Total Material Requirement (TMR), which quantifies resource consumption based on the mining activities required to obtain unit amounts of resources to produce various products that support human existence.

This research project involves identifying products that lead to the resource paradox and proposing measures to prevent it through technologies, societal systems, and policy packages, to realize a multi-value circular economy that enables the most efficient utilization possible of diverse product functions, thereby contributing to building a truly sustainable society.

-

Research results envisaged in this project

Materials/processes and recycling technologies coupled with new societal systems and institutional measures as solutions

Prof. Yamasue’s previous research has demonstrated that products can be classified into two types: those whose resource consumption is low during production but increases as they are used (“use phase-dominant”) and those whose resource consumption is relatively high during production (“production phase-dominant”). In this project, three groups of researchers are working in organic collaboration, sharing as basic data the classification of a variety of products relevant to green innovation into either of these two types.

The first group, headed by Prof. Itoh, is developing materials and processes that are suitable for either of the two resource consumption patterns. For products with “use phase-dominant” resource consumption, the group aims to realize optimal use of the most appropriate resources to reduce the consumption of electricity and other resources during use. To this end, the strength properties of materials will be clarified in terms of transformation, destruction, and durability while techniques will also be developed to assess optimal degrees of strength. For products with “production phase-dominant” resource consumption, solutions are to be sought in organizational control and the active use of recycled materials, instead of use of the resource itself. Drawing on and further developing the research achievement of Prof. Kei Ameyama, the leader of a team within this group, in a project conducted within the First-Phase R-GIRO Program, i.e., the creation of high-strength, high-ductility materials by harmonic structure design, the group intends to create ubiquitous highly functional materials, such as high-strength, high-ductility titanium-based materials and highly shock-resistant steel-based materials, thereby eliminating the need for rare metals. The group also plans to develop new material processing and precision grinding procedures that reduce or eliminate dependence on resources. Moreover, from a different perspective, the group is also focusing on lithium-ion batteries, which are heavily resource-dependent and are likely to be used in large numbers of products in the future. Using the synchrotron radiation equipment at Ritsumeikan University (the only private university so equipped in Japan), the group intends to analyze the elements comprising lithium-ion battery materials at the atomic level to elucidate the mechanism of battery deterioration.

The second group, led by Prof. Yamasue, is working on the development of high-value-added, low-cost recycling technologies from three approaches. The first one, focusing on the classification of used products by component, involves the development of a high-speed automatic sorting technology based on image recognition for electronic substrates and components. The second approach concerns the identification and separation of diverse materials contained in used products and components. For example, currently, there is no method that can be introduced into actual recycling sites to identify and separate precious metals contained in electronic substrates, such as gold, silver, and palladium. The group is attempting to establish a high-speed, high-precision scrap-sorting technology by combining image recognition technology with the technology it has developed using laser-induced breakdown spectroscopy to rapidly analyze the composition of valuable metals in an electronic substrate. The third approach focuses on efficient recycling of separated materials. One major problem with recycling is the enormous transportation costs involved in concentrating used products at centralized recycling plants. The group intends to develop highly efficient small-scale recycling technologies using microwave radiation as a heat source to build a system of decentralized recycling bases. One advantage of using microwave radiation is that its thermal efficiency does not drastically drop on a smaller scale. In preliminary research, the group has demonstrated that it takes only several dozens of seconds at the most to reduce with microwaves lithium cobalt oxide contained in lithium-ion batteries, as compared to the approximately one hour required in an ordinary electric furnace. The group is applying this process to recycling so as to develop high-speed, high-efficiency reduction processes for cobalt, nickel, lithium, manganese, lead, and rare-earth elements.

The third group, led by Prof. Hashimoto, is charged with the quantitative evaluation of various products relevant to green innovation and the new materials and technologies developed by the other two groups from the perspective of life cycle analysis, assessing how much they reduce environmental impact and increase resource efficiency. The group also researches methods to reduce resource consumption through societal systems. For example, in a case study concerning automobiles, the group predicts how the adoption of a car-sharing system in society impacts society-wide resource use intensity and life-cycle carbon dioxide emissions, and designs conditions and strategies to make the car-sharing system maximally effective. The group’s research results will be incorporated into proposals of policy packages and measures for the practical application of the other two groups’ research results.

An international research center leading the world, drawing on the TMR database

Many businesses and governments in the world are vaguely aware of the resource paradox but are unable to take action to solve the problem because they have no means to visualize it. This project team can help them with the high-quality TMR database it has built covering over 1,000 raw materials, intermediate products, and energy sources. Drawing on this powerful tool, the team hopes to present to the world products and processes that cause the resource paradox and to propose concrete, evidence-based solutions.

The members of this project team have formed partnerships with a total of 38 research institutions in 17 countries around the world. The team intends to further expand this network through this research project, thereby firmly establishing itself as an international research center leading the world in the domain of resource-related research.

The research project actively supports overseas research and study (a scene from a joint research project in France)

077-561-3488 (9:00-17:30 on weekdays)

072-665-2570 (9:00-17:30 on weekdays)

075-465-8224 (9:00-17:30 on weekdays)