Space development has three phases. Phase one focuses on the scientific observation and exploration, phase two comprises the building and maintenance of the humanosphere, and phase three concentrates on building a living environment and the realization of a worthwhile life. We are mainly focused on phase two. Several places on the Earth and in space are uninhabitable by humans. Our goal is to explore these uncharted areas and make them habitable for humans. Professor Taizo Kobayashi, Associate Professor Atsushi Kakogawa, and Associate Professor Yuma Kawasaki of the College of Science and Engineering have been working on unmanned construction technology to build the infrastructure essential for human survival, including the first lunar base on the Moon’s surface.

Research Introduction

KOBAYASHI : The construction of a lunar base was only discussed in manga and science fiction. However, with humanity seeking new spheres of activity and survival, lunar base construction has been recently considered a realistic goal. Residential areas for human habitation, research facilities, ports for transport vessels, and access roads for these essential facilities can be expected to be constructed on the Moon.

The lunar surface is covered with fine grains called “regolith.” However, only limited information is available on the characteristics of the regolith, including its thickness and firmness. This information is essential for lunar base construction.

As a researcher specializing in geotechnical engineering, I am conducting basic research on the soil mechanical characteristics (such as stiffness, compressibility, and strength), the design and operation of lunar and planetary probes, the development of lunar soil investigation equipment, and the design of facilities to be constructed on the lunar surface.

KAKOGAWA : In addition to space, several locations on the Earth are not fit for human inhabitation, such as deep waters and deep caves with low oxygen concentrations. Access to locations, such as the deep ocean with high water pressure, environments with high heat and toxicity (such as volcanoes), or the polar regions with extremely low temperatures, is hindered even with the right equipment or vehicles.

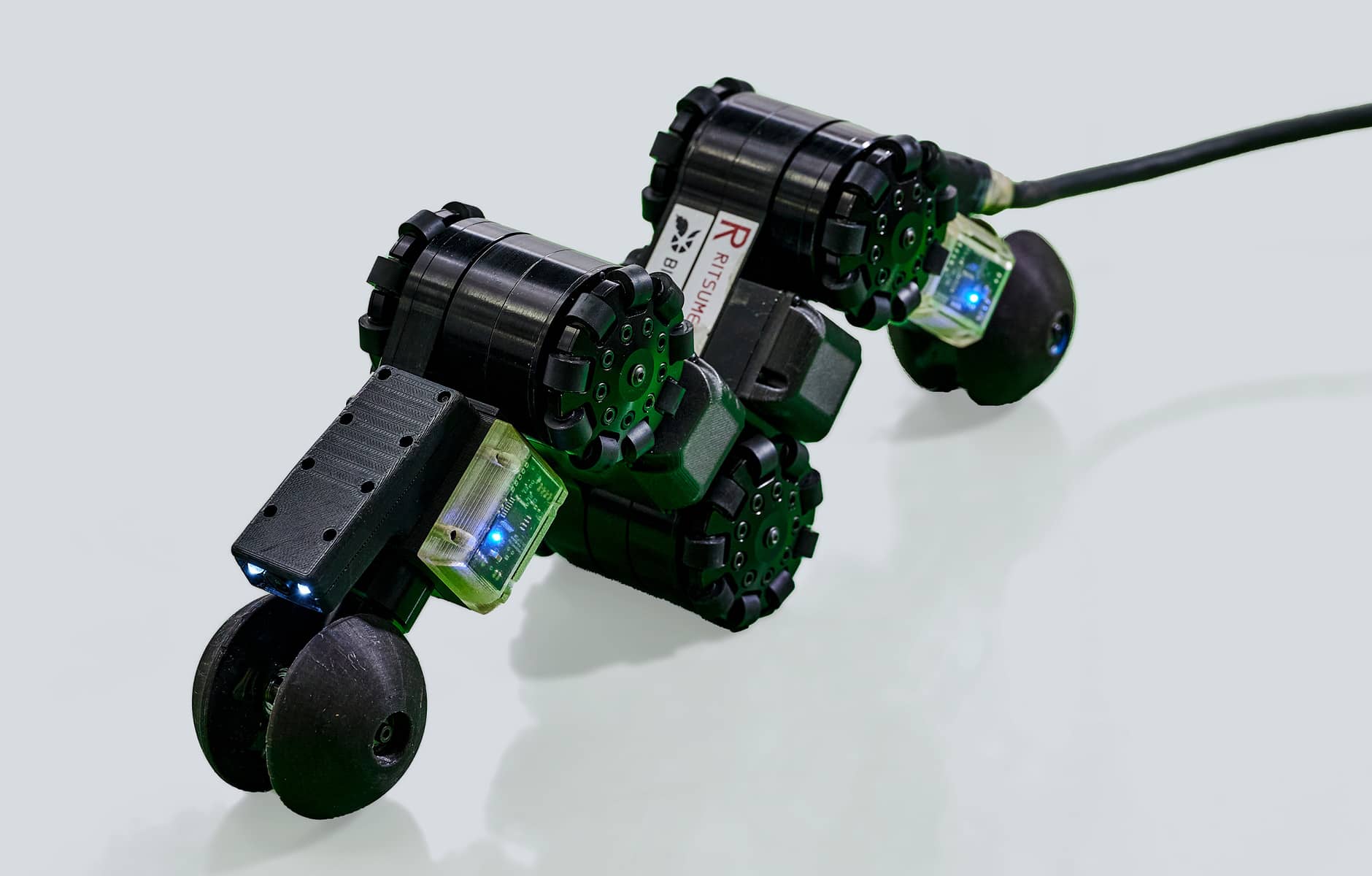

Additionally, narrow artificial spaces, such as gaps between buildings and infrastructure are inaccessible. We use hardware and technology to research and develop robots capable of performing tasks that are physically impossible for humans to perform in these extreme environments.

In my lab, we also focus on social implementation. For example, we are conducting outdoor field experiments on robots that can move forward and backward to inspect the complex winding sewer pipes.

KAWASAKI : Ordinary concrete is prepared by mixing sand, gravel, cement, and water, and is allowed to harden through a hydration reaction. Sand, gravel, water, and limestone, which are the raw materials for cement, are mostly natural resources. The depletion of sand resources has been a major concern worldwide. I have succeeded in creating a new type of concrete that uses powder made from discarded concrete, instead of sand, and polysaccharides of plant cell walls instead of cement. This concrete is hardened through heating and compression.

Heating increases the viscosity of the polysaccharides, which then function as a glue to hold the powder together when pressure is applied. Some polysaccharides may require high temperatures and high pressures to increase their viscosity. However, we have developed a mixture that can be used at room temperature (approximately 20 degrees Celsius). The flexural strength of the resulting material was higher than that of ordinary concrete.

Currently, I am working on the development of “lunar concrete,” which uses simulated lunar regolith as an aggregate instead of recycled concrete. We have already succeeded in creating a hardened body through pressurization and are currently working to improve its performance by changing the type of polysaccharide and the mixing ratio with regolith for potential utilization as building and paving materials on the Moon.

Civil Engineering Works on the Moon

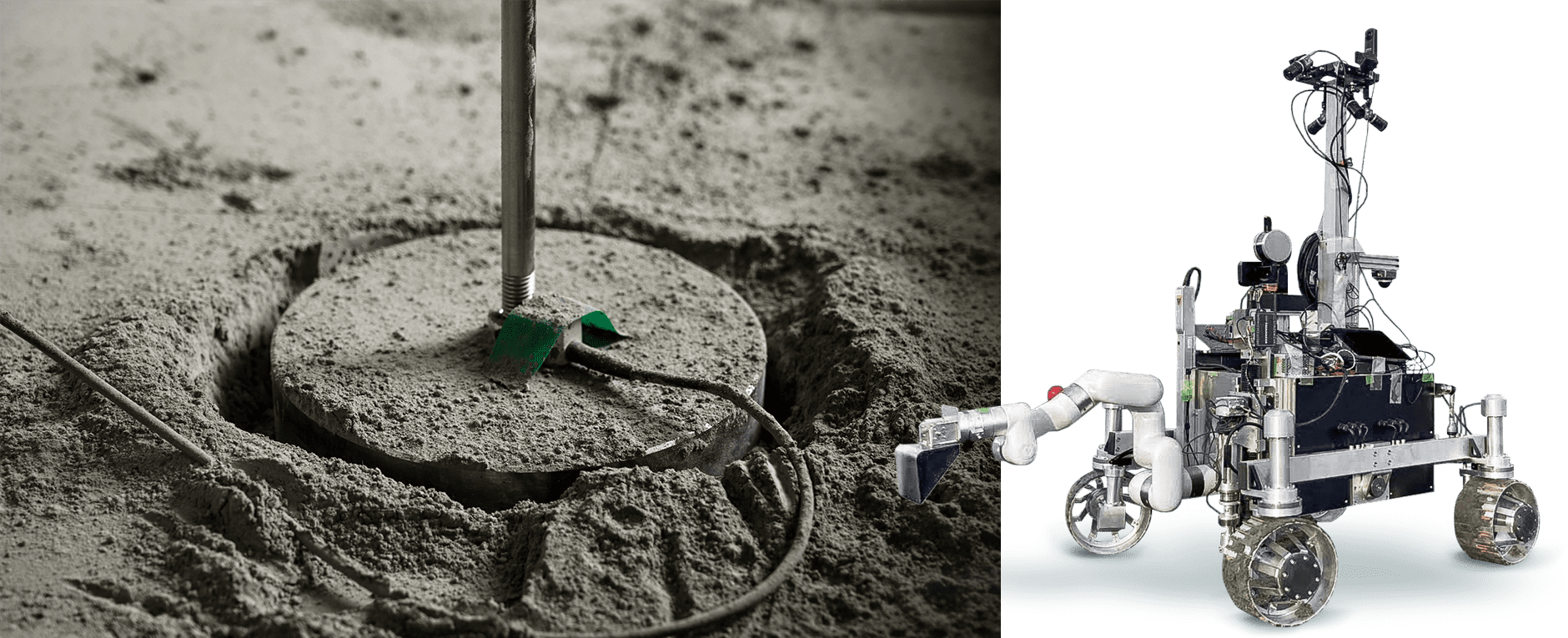

KOBAYASHI : I am working with Associate Professor Kakogawa to develop an unmanned lunar surface investigation robot. In particular, I have specifically requested him to develop a rover and a manipulator (robot arm). Our goal is to attach a bucket to the end of the robot arm for automatically performing tasks, such as leveling and excavation on the lunar surface, similar to a hydraulic excavator used on the Earth. Currently, we are in the process of developing and testing a model that is operable on the ground.

KAKOGAWA : Although we are exploring the potential use of robots on the Moon, much of the new technology has not been developed. The currently implemented technological innovation comprises a combination of existing technology. As there are many hurdles in an extreme environment, we do not actively incorporate cutting-edge devices with high-performance central processing units but use the “Karakuri” mechanism involving low-tech devices. The major limitation of using the system on the Moon is the distance between the Earth and the Moon. Remote manual operation from the Earth is challenging due to the time lag in communication. The system must be capable of autonomous operations. We are about to test automatic operations. We also want to ensure high reliability so that it can be entrusted with exploration, surveying, and other tasks not only on the Moon but also in places on the Earth that are inaccessible to humans, such as the ocean floor and polar regions, as well as in harsh environments.

KOBAYASHI : So, we are aiming to create a dual-use robot that can be used both in space and on the Earth.

Now let us hear from Associate Professor Kawasaki, who is developing a concrete material that can be used as a building material and a paving material. This concrete material is a hardened substance that does not rely on water and cement, which are difficult to obtain. The novel concrete is developed using regolith, which is abundant on the lunar surface, and a small amount of water that can be procured on-site.

KAWASAKI : Yes, I have already succeeded in producing the hardened material using the same method as that used for recycled concrete, which involves heating and compression. I have presented it at public events, such as the Golden Expo held in Tsukuba City in April 2024. The challenge, however, is to find a source for the plant-based powder. As water is not completely unnecessary, another concern is its availability on the Moon. Materials that cannot be obtained on the Moon may have to be sourced from the Earth although we may consider producing them on-site in the future.

KOBAYASHI : The production of lunar concrete would be one way to effectively utilize water on the Moon and I think that could be a selling point.

KAWASAKI : Most of my research is focused on applications both on the Moon and on the Earth. In addition to the lunar regolith, we are also considering the use of desert sand, which cannot be used as a material for conventional concrete because the grains are too uniform in size, as well as the use of debris from natural disasters and even coffee powder, as raw materials. As countless potential plant materials can be used as a source of polysaccharides, we are investigating the optimal sources to increase strength and/or the effect of the combination of multiple materials on the properties of the final product. The manufacturing process also requires further research. Currently, the material is mixed, placed in a mold, and compressed to produce a brick-like, rectangular, hardened body. However, to pave the lunar surface, methods, such as a vibrating press, which is similar to the method of asphalt paving on the Earth, must be considered. The effect of harsh environments, such as meteorite impacts and huge temperature differences, ranging from 100 degrees Celsius during the day to –180 degrees Celsius at night, must also be tested.

KAKOGAWA : We still have a lot of issues to address related to adapting to the lunar environment. Currently, we are at the stage of ground testing. The air, stable temperatures, and low radiation in these testing conditions provide a fairly simple and tractable environment. However, the Moon’s surface is completely different from the Earth’s surface with no air, low gravity, high cosmic radiation, and powdery regolith. Having said that, low gravity has its advantages, such as the ability to lift heavy objects with smaller motors than those used for lifting on the Earth.

The absence of air and space radiation, however, is a major problem. This is because most robots use reduction gears to amplify the torque of the motor, which almost always contains lubricating oil. In an extremely low-pressure environment, such as a vacuum, fluids can easily evaporate and leak outside. Additionally, robots on the ground use various sensors and electronic circuit boards to accurately control their position and speed. Space radiation can damage these components.

For construction applications, excavators and cranes can be used. However, general construction equipment is powered by hydraulic actuators. Hydraulic oil, like lubricant, evaporates and is lost in a vacuum environment and leaks out. Nowadays, electric motors are being used in construction machinery on the Earth, and yet the power of electric robots is considerably lower than that of hydraulic robots. Hence, the performance of electric robots on the Moon must be verified.

To Build a Lunar Base and Pavement

KOBAYASHI : To explore the Moon and build a lunar base, the geological and geotechnical conditions of the lunar surface must be understood. Our robot is approximately one meter wide and weighs approximately 100 kilograms. This robot performs 3D geological and geotechnical investigations and records the results on a three-dimensional map. Additionally, this robot is equipped with devices for positioning and surveying, seismic testing, shear testing, load testing, and radioisotope (RI) density measurement. These tools enable us to visualize the subsurface environment.

To recreate the lunar surface environment, we are conducting experiments using a lunar regolith simulant, which artificially reproduces the size, weight, and chemical composition of soil particles. The slag produced as a byproduct in metal smelting plants resembles lunar regolith. As the slag is abundantly available, large-scale experiments can be conducted. This plant has an area of several hundred square meters where the slag has accumulated up to a depth of several meters. We have obtained permission to use the slag to create the required terrain. We hope to create a crater and other lunar-like environments in this terrain soon and test the rover.

KAKOGAWA : To achieve autonomous driving, I would like to conduct experiments where we attach a camera or LiDAR (Light Detection And Ranging) to the robot and let the robot estimate its position.

KOBAYASHI : I have heard that construction machinery manufacturers are also starting to place cameras or LiDAR on their machines for position estimation.

KAKOGAWA : Exactly. But the primary difference between our challenge and theirs is that the cameras and LiDAR may not withstand cosmic radiation for our project. We may need to consider a different method that does not rely solely on optical technology.

Additionally, estimating the position and drawing a map are two completely different challenges. It is difficult to build a mechanism into a robot that allows it to move autonomously while drawing a map. On the Earth, you first establish a reference point and then measure the coordinates from that point. On the Moon, however, the first question is how to create a reference point as the surface of the Moon is a uniform gray color with few variants in appearance. It may be better to use an artificial reference point. We are currently investigating the type of color or the placement of these reference points.

There is also a method of drawing a map called simultaneous localization and mapping, which allows the robot to determine its position and draw a map simultaneously. The robot detects its environment and decides its move. As it moves, the robot acquires more information about its environment and uses that to update the map. When the map is updated, it can ascertain its position within that map and subsequently decide its next move.

Right: Plate loading and shear testing tool(breadboard model): A testing device mounted on exploration rovers to measure deformation and strength characteristics of the lunar and planetary surfaces. It features two primary functions: (1) a plate penetration to obtain load-settlement relationships for assessing soil stiffness, and (2) a plate rotation under constant pressure to obtain shear stress-shear deformation relationships for evaluating soil strength.

KAWASAKI : I am still at the stage of considering the best type of materials. Hence, it is hard for me to think about specific uses on the Moon like you two. But, if we are thinking about using them for paving and construction, I think we would first need equipment to produce large quantities of concrete on the Moon.

I mentioned earlier the idea of using a vibratory press to apply pressure. As the Moon has low gravity, compacting the material is challenging using the weight of the press. A macadam roller with teeth would render the finished surface uneven although it is useful to apply some pressure to the material. Alternatively, instead of laying the material directly on the lunar surface and applying pressure, a precast method can be used where several small bricks are prepared in advance and then assembled on-site. In this case, we would build a pressure factory, and the mixing, heating, and pressurizing of the material would be done in that facility.

In the United States, NASA is working with a private construction company to carry out Project Olympus, which aims to use 3D printing to construct living spaces on the Moon and Mars. Currently, they are in the stage of performing simulations on the Earth. Based on my information, they hope to complete the preparations by landing on the Moon by 2026. In the future, the most appropriate construction method can be selected depending on the type and size of the required object.

What We Should Consider for the Future

KOBAYASHI : Until now, the value of lunar exploration was centered on scientific exploration to reach the Moon and unravel the mysteries of its origin and evolution. However, to make the Moon a humanosphere, we are required not only to conduct scientific exploration but also to consider how to utilize the Moon’s resources and how to make use of scientific data. Research institutions in Japan and overseas, including JAXA, are gradually starting to talk about ideas based on data, such as how to use the water discovered on the Moon. However, several of these ideas have not been transformed into more concrete plans. I think the difference between an idea and a plan is whether it is based on a proper investigation. To build structures on the Moon, an on-site investigation and a design theory are needed. As a civil engineering researcher, I intend to continue my research on the lunar surface and pursue structural design theory.

Some of the researchers at the Earth and Space Exploration Center (ESEC) are developing sensors and spectrometers to explore lunar mineral resources. We would like to work with them to develop a drilling robot using science and engineering.

KAKOGAWA : Currently, a limited number of organizations focus on the design and development of equipment to be installed on landers and rovers, such as observers, robots, and working machines. BKC is a huge campus, and in some cases, we also use fields outside the University. We are fortunate in terms of our field-testing environment. It is important to test robots in an environment that is similar to the actual field rather than a university laboratory. I would like ESEC to serve as a base for lunar and other planetary exploration by connecting fields in different parts of the Kansai region with BKC at the center. In the future, we can propose collaborations with colleagues overseas.

KAWASAKI : At ESEC, we have researchers from various fields of Sciences and Humanities. In the future, I would like to focus not only on individual research results but also on collaboration among researchers. I would like to participate in such collaborative activities when my expertise is coveted, and I hope to develop ideas that would encourage other researchers to collaborate.

KOBAYASHI : We are both engineers and scientists. We have personnel who can not only develop tools but also interpret the data for further research. I am confident that through ESEC we can add value to lunar exploration.